Characteristics of the shuttle

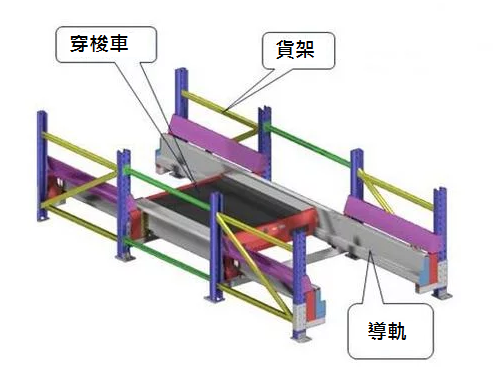

The composition and picking mode of the shuttle pallet storage system. The shuttle car is also called Rail Guide Vehicle (RGV) because of its flat shape, also known as the shuttle version. The shuttle pallet storage system is a high-density storage system composed of storage shelves, trolleys and forklifts, and the utilization of warehouse space is high. The shuttle cart and its shelf system are mainly used for the storage of low-volume and large-volume items, as well as strict requirements on shelf cycle or high space utilization (such as ensuring continuous supply of materials on the production line). The stacker goes out of the warehouse to perform storage operations.

The combination of dense racks and shuttles enables high-density, automated storage of pallet units. According to the arrangement of the item's access port, it can be divided first-in-first-out mode and last-in-first-out mode. The first-in-first-out mode is that the pallet is deposited from one end of the aisle and the other end is taken out to realize the first-in-first-out logistics principle. The storage advantage of the shuttle is that it can realize the sequential access to logistics, which conforms to the general logistics principles, can realize the operation of partitioning logistics access, and optimizes site management. The disadvantage is that forklift channels need to be arranged at both ends of the shelf. Geographical last-in-first-out principle of dynamic storage usage. The last-in-first-out mode is to arrange the forklift aisle on one side of the shelf and only access the goods from one side of the aisle. The advantage is that the aisle is only arranged on one side of the shelf, and the storage area can be maximized.

In developed countries, the shuttle has been standardized and serialized, and the corresponding model can be ed according to the shape and weight of the item. For special size and weight items, the corresponding shuttle can be specially designed.